रà¥à¤à¤°à¥ à¤à¥à¤¬à¤²à¥à¤ à¤à¤®à¥à¤ªà¥à¤°à¥à¤¶à¤¨ मशà¥à¤¨ फà¥à¤¡ फà¥à¤°à¥à¤®

Price 12000.0 आईएनआर/ Unit

MOQ : 1 Unit

रà¥à¤à¤°à¥ à¤à¥à¤¬à¤²à¥à¤ à¤à¤®à¥à¤ªà¥à¤°à¥à¤¶à¤¨ मशà¥à¤¨ फà¥à¤¡ फà¥à¤°à¥à¤® Specification

- शोर का स्तर

- Low

- फ़्रिक्वेंसी

- 50/60 Hz

- उपयोग/अनुप्रयोग

- Feeding granules/powder mix into die cavity on rotary tablet press

- तापमान

- Ambient Operating Temperature

- फेज

- Single/Three Phase (as per machine)

- विशेषताएँ

- Easy-to-clean, corrosion-resistant, durable, precision fit, GMP compliant

- टाइप करें

- मटेरियल

- Stainless Steel (SS 316/304)

- क्षमता

- Suitable for multi-station rotary tablet press

- कम्प्यूटरीकृत

- कंट्रोल मोड

- वोल्टेज

- 220-240 V

- पावर

- 0.5 - 1 HP (Motor Driven, if applicable)

- वजन (किग्रा)

- Approx. 10-25 Kg (depending on model)

- आयाम (एल* डब्ल्यू* एच)

- Standard/Custom as per machine compatibility

- रंग

- Silver Metallic

रà¥à¤à¤°à¥ à¤à¥à¤¬à¤²à¥à¤ à¤à¤®à¥à¤ªà¥à¤°à¥à¤¶à¤¨ मशà¥à¤¨ फà¥à¤¡ फà¥à¤°à¥à¤® Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- कैश इन एडवांस (CID)

- आपूर्ति की क्षमता

- 5000 प्रति महीने

- डिलीवरी का समय

- 7-10 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About रà¥à¤à¤°à¥ à¤à¥à¤¬à¤²à¥à¤ à¤à¤®à¥à¤ªà¥à¤°à¥à¤¶à¤¨ मशà¥à¤¨ फà¥à¤¡ फà¥à¤°à¥à¤®

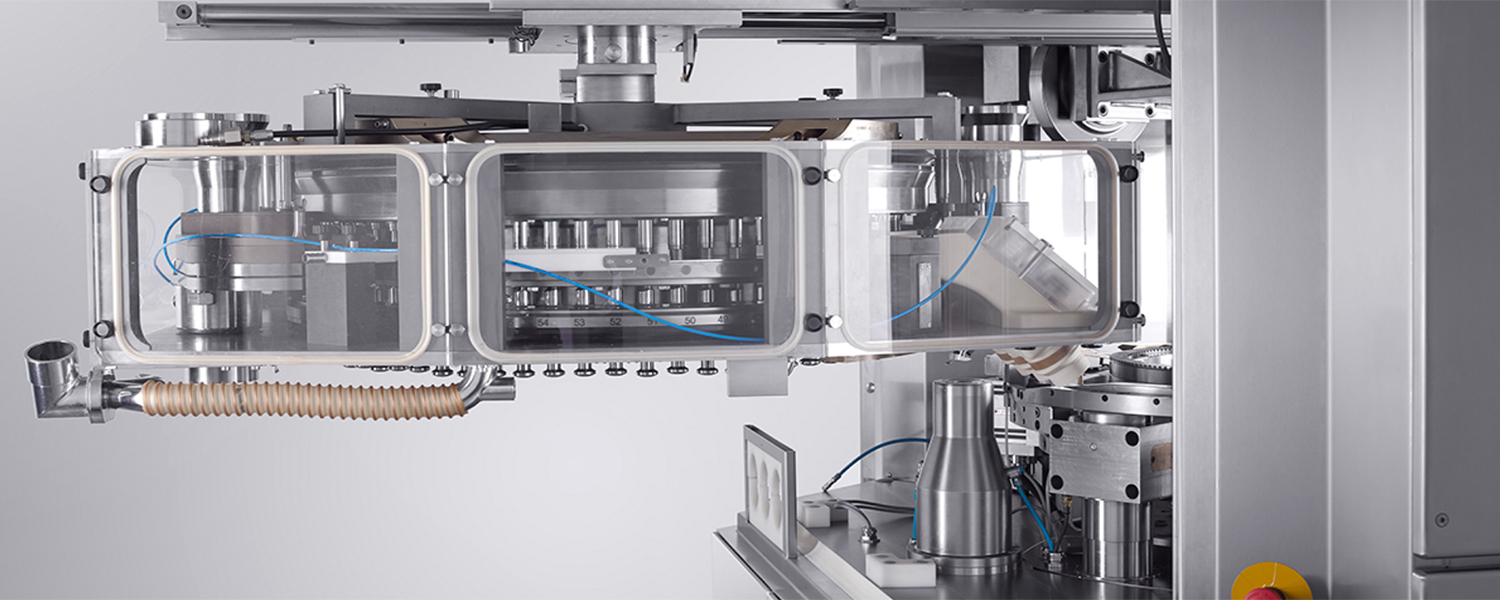

Experience ineffable efficiency with our Classic Rotary Tablet Compression Machine Feed Frame. Crafted from fresh stainless steel (SS 316/304), this uncommon innovation offers instant savings through its competitive pricing and low-maintenance operation. With a hopper capacity ranging from 5 to 15 litres, it features twin paddle or agitator spreading, mirror or matt polished options, and simple CIP cleaning. Installation is seamless-replace or detach feed frames on existing presses with ease. GMP compliance, comprehensive operator safety, and corrosion resistance promise enduring reliability for any tablet manufacturing environment.

Applications: Versatile Utility in Pharmaceutical Manufacturing

The Rotary Tablet Compression Machine Feed Frame finds extensive plant application in pharmaceutical and nutraceutical production. Designed for precision feeding of granules or powder mix, it is frequently used by large-scale drug manufacturers, research facilities, and contract production units to ensure quality tablet output. Its robust build and adaptability make it indispensable in commercial tablet press operations, maintaining batch consistency and meeting rigorous manufacturing standards with multifaceted ease.

Export Markets and Dispatch Essentials

The Arrival of our Feed Frame is highly esteemed in global markets, including Asia, Europe, and the Middle East. With export valuation supported by competitive pricing, each unit is meticulously packed for sea-worthy dispatch, ensuring secure transit. With strong supply ability and sample availability upon request, we streamline Packing & Dispatch for reliable international fulfillment. Timely delivery, responsive support, and rigorous packaging protocols define our export process, upholding our manufacturer's reputation across borders.

Applications: Versatile Utility in Pharmaceutical Manufacturing

The Rotary Tablet Compression Machine Feed Frame finds extensive plant application in pharmaceutical and nutraceutical production. Designed for precision feeding of granules or powder mix, it is frequently used by large-scale drug manufacturers, research facilities, and contract production units to ensure quality tablet output. Its robust build and adaptability make it indispensable in commercial tablet press operations, maintaining batch consistency and meeting rigorous manufacturing standards with multifaceted ease.

Export Markets and Dispatch Essentials

The Arrival of our Feed Frame is highly esteemed in global markets, including Asia, Europe, and the Middle East. With export valuation supported by competitive pricing, each unit is meticulously packed for sea-worthy dispatch, ensuring secure transit. With strong supply ability and sample availability upon request, we streamline Packing & Dispatch for reliable international fulfillment. Timely delivery, responsive support, and rigorous packaging protocols define our export process, upholding our manufacturer's reputation across borders.

FAQ's of Rotary Tablet Compression Machine Feed Frame:

Q: How does the feed frame integrate with existing rotary tablet press machines?

A: The feed frame is designed with a replaceable and detachable mechanism, allowing seamless installation on various rotary tablet press models without extensive modifications.Q: What cleaning methods are supported by the feed frame?

A: Cleaning is facilitated by either CIP (Clean-In-Place) systems or simple disassembly for manual washing, ensuring compliance with hygiene standards and operational convenience.Q: Where can this feed frame be effectively utilized?

A: It is commonly used in pharmaceutical, nutraceutical, and research plants where high-throughput tablet production and precise powder or granule feeding are essential.Q: What are the main benefits of the Rotary Tablet Compression Machine Feed Frame?

A: Key benefits include instant savings through low maintenance, precision granular distribution, corrosion resistance, competitive pricing, and durable stainless steel construction that meets GMP standards.Q: What is the process for ordering and receiving a sample?

A: You can request a sample as part of the initial inquiry. Upon confirmation, the sample is packed in export sea-worthy packaging and dispatched promptly to your location, ensuring safe and timely arrival.Q: How does the feed frame enhance operator safety?

A: Operator safety guards are integrally provided, minimizing risk during operation and ensuring compliance with workplace safety protocols.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in रोटरी टैबलेट संपीड़न मशीन के पुर्जे Category

रोटरी टैबलेट कम्प्रेशन मशीन प्रेशर रोल

न्यूनतम आदेश मात्रा : 100

मूल्य की इकाई : टुकड़ा/टुकड़े

माप की इकाई : टुकड़ा/टुकड़े

कंट्रोल मोड : ,

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : Stainless Steel

फ़ीड फ़्रेम

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : Unit/Units

माप की इकाई : Unit/Units

कंट्रोल मोड : Manual

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : Brass

लोअर कैम

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : Meter/Meters

माप की इकाई : Bunch

कंट्रोल मोड : Manual

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : Hardened Alloy Steel

जांच भेजें

जांच भेजें